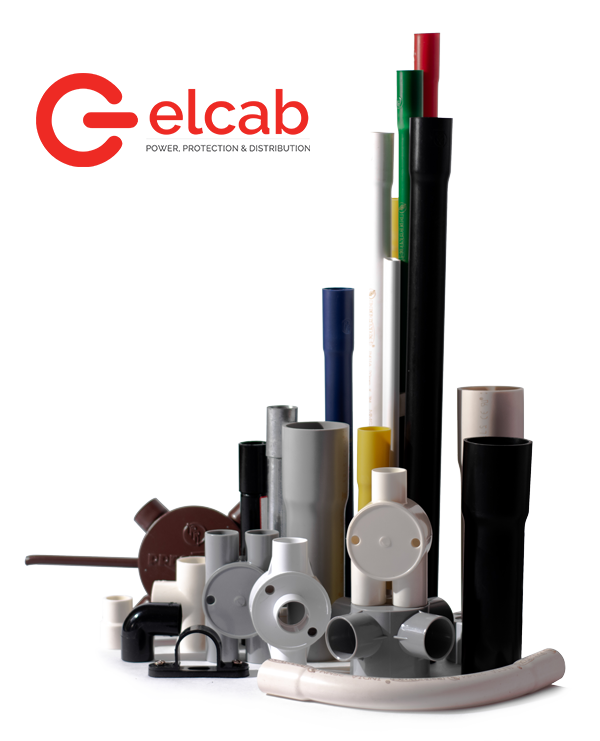

Elcab India Private Ltd. is a leading supplier and distributor of electrical conduits of various brands for a wide range of applications. Products are manufactured in accordance with IS: 9537 Part 3, BS: EN 61386 – 21 for uPVC conduits, IS: 3419 and BS: 4607 for uPVC fittings with high impact materials which make them safe to use in harsh environments.

Non-corrosive in nature, our Electrical PVC Pipes are non-combustible and possess the added quality to self-extinguish. Strong and durable, they are highly used in channelising concealed & surface wiring and for telecommunication & cable ducting.

Strong, durable, and impact-resistant; comes in various diameters & grades; easy to install, fire retardant and corrosion free; thermal resistant from -5˚c to +60˚c; Precision PVC Conduit Pipes circular boxes & adaptable boxes are provided with m4 brass insert with a load suspension capacity of 3 kgs at 60˚c.